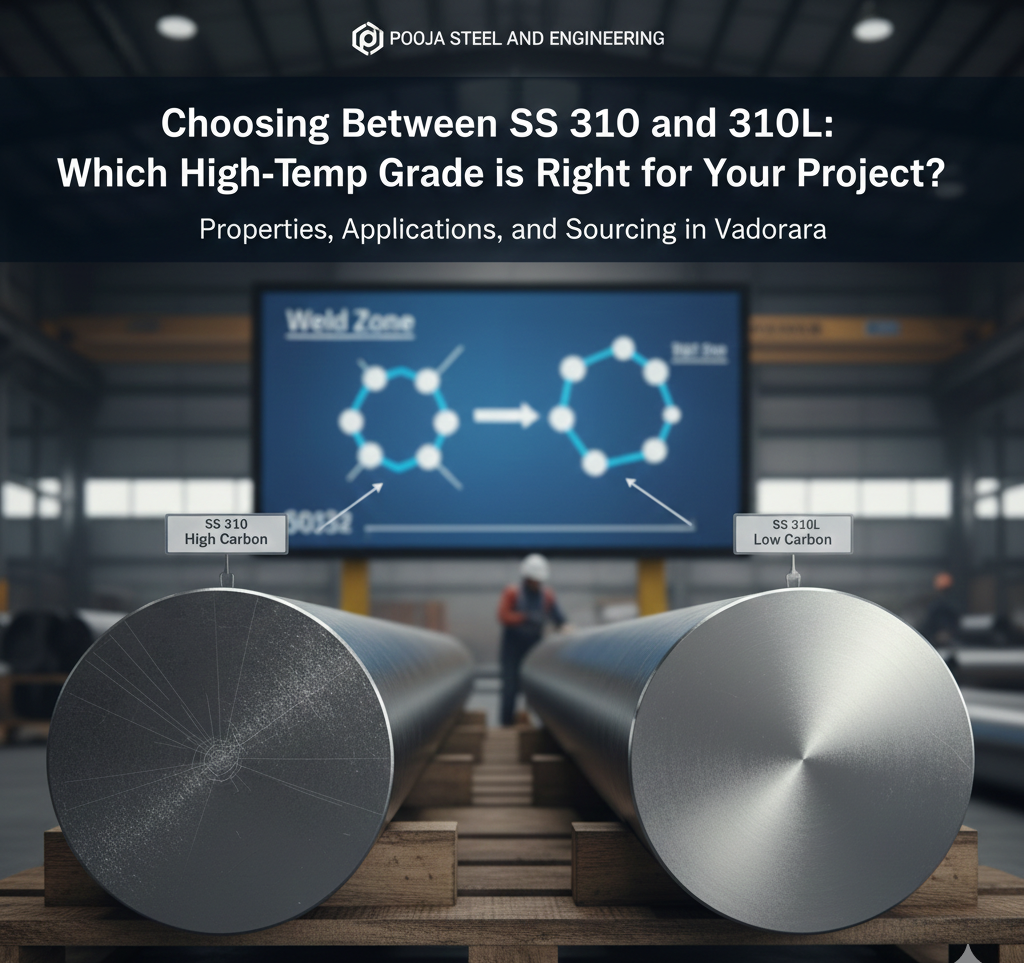

When your industrial application involves extreme heat, standard stainless steel grades like 304 or 316 simply won't cut it. You need the heavy hitters: SS 310 or SS 310L. At Pooja Steel and Engineering, a premier supplier in Vadodara, we often get asked by procurement managers: 'Is the 'L' version really necessary for my furnace components?' In this guide, we break down the critical differences to help you make an informed investment. The Core Difference: It’s All in the Carbon The 'L' in 310L stands for Low Carbon. While both grades share the same high Chromium (25%) and Nickel (20%) foundation, their carbon content dictates how they behave during fabrication and service. • SS 310: Contains up to 0.25% Carbon. This gives it slightly higher creep strength at very high temperatures. • SS 310L: Contains a maximum of 0.03% Carbon. This version is specifically designed to eliminate 'sensitization'—the precipitation of chromium carbides at grain boundaries during welding. Why SS 310L is the Preferred Choice for Fabricators in GIDC If your project involves heavy welding (such as constructing large pressure vessels or heat exchangers in Vadodara's chemical belt), SS 310L Round Bars are your best bet. Because of the low carbon content, you can weld these bars without worrying about subsequent corrosion at the weld joints. This saves your team from the expensive and time-consuming process of post-weld annealing. Environmental Factors in Vadodara Industries In the humidity and industrial atmosphere of Gujarat, intergranular corrosion can be a silent killer for steel structures. By opting for UNS S31008 (310L), you are adding an extra layer of protection against the corrosive fumes common in fertilizer and petrochemical plants. Why Sourcing Locally from Pooja Steel Matters As a local SS 310 Round Bar stockist in Vadodara, we offer benefits that out-of-state suppliers can't match: 1. Immediate Inspection: Visit our warehouse in Makarpura to inspect the finish and quality of our bright bars. 2. Reduced Logistics Costs: No heavy freight charges from distant ports; we provide local delivery across Gujarat. 3. Custom Cutting: We provide SS 310L rods cut to your specific length, reducing material wastage for your workshop. Final Verdict SS 310 vs 310L Round Bar: Which Should You Choose? Understand the difference between SS 310 and 310L. Expert advice from Vadodara's leading SS 310 Round Bar stockist. Read our technical comparison today! Difference between 310 and 310L, SS 310L Round Bar suppliers Gujarat, UNS S31008 properties, high temperature stainless steel rods.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.poojapipesandfittings.com/latest-update/choosing-between-ss-310-and-ss-310l-which-high-temp-grade-is-right-for-your-project/90

Choosing Between SS 310 and SS 310L: Which High-Temp Grade is Right for Your Project?

2026-01-16T05:01:05

When your industrial application involves extreme heat, standard stainless steel grades like 304 or 316 simply won't cut it. You need the heavy hitters: SS 310 or SS 310L. At Pooja Steel and Engineering, a premier supplier in Vadodara, we often get asked by procurement managers: 'Is the 'L' version really necessary for my furnace components?' In this guide, we break down the critical differences to help you make an informed investment. The Core Difference: It’s All in the Carbon The 'L' in 310L stands for Low Carbon. While both grades share the same high Chromium (25%) and Nickel (20%) foundation, their carbon content dictates how they behave during fabrication and service. • SS 310: Contains up to 0.25% Carbon. This gives it slightly higher creep strength at very high temperatures. • SS 310L: Contains a maximum of 0.03% Carbon. This version is specifically designed to eliminate 'sensitization'—the precipitation of chromium carbides at grain boundaries during welding. Why SS 310L is the Preferred Choice for Fabricators in GIDC If your project involves heavy welding (such as constructing large pressure vessels or heat exchangers in Vadodara's chemical belt), SS 310L Round Bars are your best bet. Because of the low carbon content, you can weld these bars without worrying about subsequent corrosion at the weld joints. This saves your team from the expensive and time-consuming process of post-weld annealing. Environmental Factors in Vadodara Industries In the humidity and industrial atmosphere of Gujarat, intergranular corrosion can be a silent killer for steel structures. By opting for UNS S31008 (310L), you are adding an extra layer of protection against the corrosive fumes common in fertilizer and petrochemical plants. Why Sourcing Locally from Pooja Steel Matters As a local SS 310 Round Bar stockist in Vadodara, we offer benefits that out-of-state suppliers can't match: 1. Immediate Inspection: Visit our warehouse in Makarpura to inspect the finish and quality of our bright bars. 2. Reduced Logistics Costs: No heavy freight charges from distant ports; we provide local delivery across Gujarat. 3. Custom Cutting: We provide SS 310L rods cut to your specific length, reducing material wastage for your workshop. Final Verdict SS 310 vs 310L Round Bar: Which Should You Choose? Understand the difference between SS 310 and 310L. Expert advice from Vadodara's leading SS 310 Round Bar stockist. Read our technical comparison today! Difference between 310 and 310L, SS 310L Round Bar suppliers Gujarat, UNS S31008 properties, high temperature stainless steel rods.

2026-01-16T05:01:05

Submit Your Enquiry