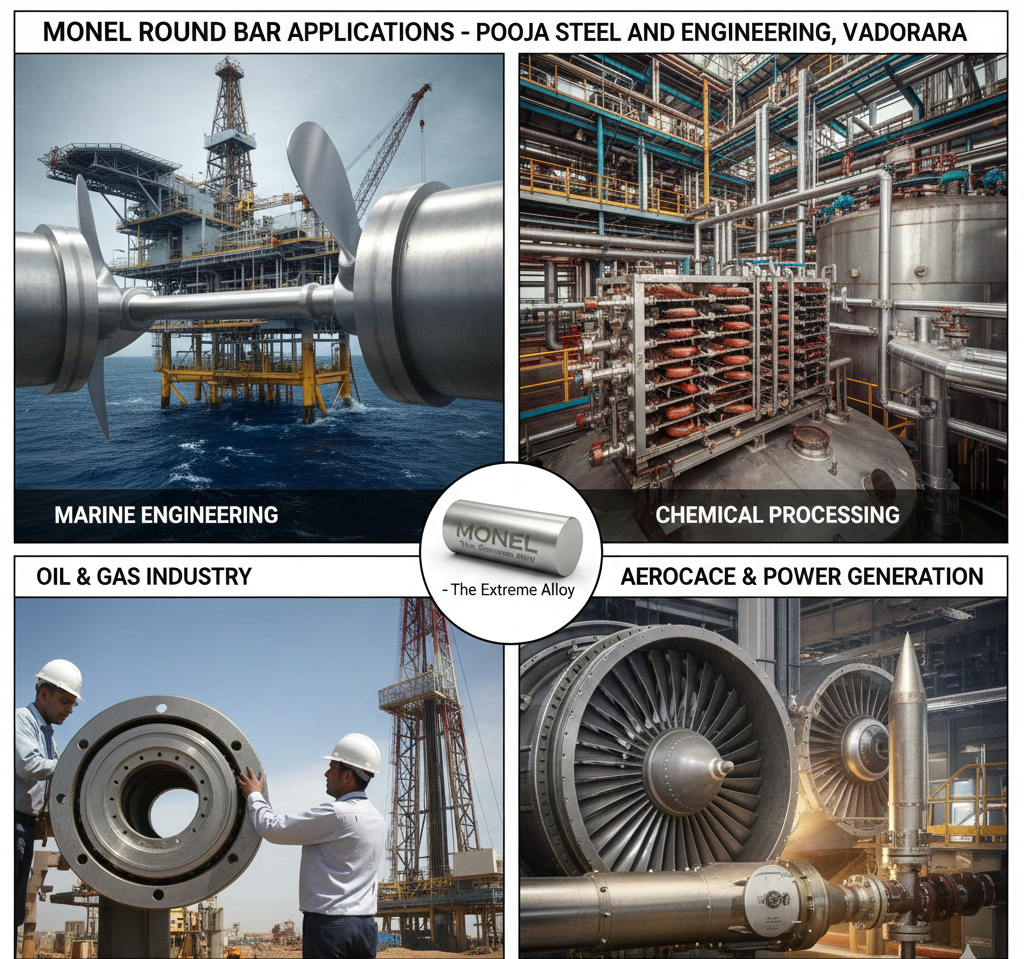

In the demanding world of industrial manufacturing, selecting the right alloy can be the difference between a system that lasts decades and one that fails in months. At Pooja Steel and Engineering, we specialize in high-performance materials like Monel round bars, which have become the industry standard for environments where corrosion resistance and mechanical strength are non-negotiable. This guide explores the technical DNA of Monel round bars—specifically the popular Monel 400 and Monel K500 grades—and why they are the preferred choice for engineers in Vadodara and global markets. 1. Chemical Composition: The Foundation of Resistance The secret to Monel’s success lies in its unique ratio of nickel and copper. Unlike stainless steel, which relies heavily on chromium, Monel is a 'natural' alloy that mimics the proportions found in specific nickel ores. The Difference Maker: Aluminum & Titanium While Monel 400 is a solid-solution alloy, Monel K500 adds small amounts of Aluminum and Titanium. These elements allow for precipitation hardening (age hardening), which gives K500 significantly higher strength without sacrificing its legendary corrosion resistance. 2. Mechanical Properties: Built for Extreme Conditions Monel round bars are prized for their ability to maintain structural integrity from cryogenic temperatures up to 538°C (1000°F). Key Performance Metrics: • Tensile Strength: Monel 400 typically ranges from 550–620 MPa, whereas age-hardened Monel K500 can reach up to 1100 MPa. • Ductility: Even at sub-zero temperatures, these bars do not become brittle, making them ideal for Arctic or deep-sea applications. • Non-Magnetic Nature: Monel K500 remains reliably non-magnetic even at very low temperatures, which is critical for sensitive electronic equipment and oil-well drilling tools. 3. Industrial Applications: Where Monel Shines Because of its resistance to hydrofluoric acid, seawater, and alkalis, Monel round bars are used in the most aggressive environments on Earth. A. Marine Engineering Monel 400 is almost immune to chloride-ion stress corrosion cracking. • Uses: Propeller shafts, pump shafts, seawater valves, and fasteners for offshore rigs. B. Chemical Processing The alloy’s ability to handle concentrated acids makes it a staple in chemical plants. • Uses: Heat exchangers, chlorinated hydrocarbon processing, and valve stems for hydrofluoric acid service. C. Oil & Gas Industry In 'sour gas' environments where H2S is present, Monel K500 provides the necessary strength and resistance. • Uses: Drill collars, oil-well surveying instruments, and high-strength fasteners. D. Aerospace & Power Generation The high strength-to-weight ratio and temperature resistance make it ideal for extreme machinery. • Uses: Turbine blades, rocket motor components, and exhaust systems. Why Choose Pooja Steel and Engineering for Monel Bars? As a trusted supplier in Vadodara, we ensure that every ASTM B164 Monel Round Bar we supply meets stringent international standards. Whether you need the weldability of Alloy 400 or the high-strength performance of K500, we provide: • Precision Machined Dimensions: From 3mm to 400mm diameters. • Full Certification: Every bar comes with Mill Test Certificates (MTC). • Local Expertise: Fast delivery to GIDC estates in Makarpura, Savli, and beyond. Are you looking for a quote on Monel 400 or K500 round bars? Contact Pooja Steel and Engineering today for the most competitive prices in Vadodara! Would you like me to generate a specific price list or a comparison chart for different diameters of Monel bars?

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.poojapipesandfittings.com/latest-update/monel-round-bars-a-deep-dive-into-chemical-composition-mechanical-properties-and-industrial-appli/96

Monel Round Bars: A Deep Dive into Chemical Composition, Mechanical Properties, and Industrial Appli

2026-01-27T04:11:18

In the demanding world of industrial manufacturing, selecting the right alloy can be the difference between a system that lasts decades and one that fails in months. At Pooja Steel and Engineering, we specialize in high-performance materials like Monel round bars, which have become the industry standard for environments where corrosion resistance and mechanical strength are non-negotiable. This guide explores the technical DNA of Monel round bars—specifically the popular Monel 400 and Monel K500 grades—and why they are the preferred choice for engineers in Vadodara and global markets. 1. Chemical Composition: The Foundation of Resistance The secret to Monel’s success lies in its unique ratio of nickel and copper. Unlike stainless steel, which relies heavily on chromium, Monel is a 'natural' alloy that mimics the proportions found in specific nickel ores. The Difference Maker: Aluminum & Titanium While Monel 400 is a solid-solution alloy, Monel K500 adds small amounts of Aluminum and Titanium. These elements allow for precipitation hardening (age hardening), which gives K500 significantly higher strength without sacrificing its legendary corrosion resistance. 2. Mechanical Properties: Built for Extreme Conditions Monel round bars are prized for their ability to maintain structural integrity from cryogenic temperatures up to 538°C (1000°F). Key Performance Metrics: • Tensile Strength: Monel 400 typically ranges from 550–620 MPa, whereas age-hardened Monel K500 can reach up to 1100 MPa. • Ductility: Even at sub-zero temperatures, these bars do not become brittle, making them ideal for Arctic or deep-sea applications. • Non-Magnetic Nature: Monel K500 remains reliably non-magnetic even at very low temperatures, which is critical for sensitive electronic equipment and oil-well drilling tools. 3. Industrial Applications: Where Monel Shines Because of its resistance to hydrofluoric acid, seawater, and alkalis, Monel round bars are used in the most aggressive environments on Earth. A. Marine Engineering Monel 400 is almost immune to chloride-ion stress corrosion cracking. • Uses: Propeller shafts, pump shafts, seawater valves, and fasteners for offshore rigs. B. Chemical Processing The alloy’s ability to handle concentrated acids makes it a staple in chemical plants. • Uses: Heat exchangers, chlorinated hydrocarbon processing, and valve stems for hydrofluoric acid service. C. Oil & Gas Industry In 'sour gas' environments where H2S is present, Monel K500 provides the necessary strength and resistance. • Uses: Drill collars, oil-well surveying instruments, and high-strength fasteners. D. Aerospace & Power Generation The high strength-to-weight ratio and temperature resistance make it ideal for extreme machinery. • Uses: Turbine blades, rocket motor components, and exhaust systems. Why Choose Pooja Steel and Engineering for Monel Bars? As a trusted supplier in Vadodara, we ensure that every ASTM B164 Monel Round Bar we supply meets stringent international standards. Whether you need the weldability of Alloy 400 or the high-strength performance of K500, we provide: • Precision Machined Dimensions: From 3mm to 400mm diameters. • Full Certification: Every bar comes with Mill Test Certificates (MTC). • Local Expertise: Fast delivery to GIDC estates in Makarpura, Savli, and beyond. Are you looking for a quote on Monel 400 or K500 round bars? Contact Pooja Steel and Engineering today for the most competitive prices in Vadodara! Would you like me to generate a specific price list or a comparison chart for different diameters of Monel bars?

2026-01-27T04:11:18

Keywords

- Monel valve stems for hydrofluoric acid

- Monel propeller shaft material

- Monel fasteners for offshore rigs

- Monel heat exchanger applications

- Monel bar dimensions and sizes

- ASTM B164 Monel round bars

- Monel aerospace power generation components

- Monel oil and gas industry use

- Monel for chemical processing applications

- Monel alloy for marine engineering

- Corrosion resistant Monel bars

- Monel K500 mechanical properties

- Monel 400 chemical composition

- High-performance Monel alloy grades

- Monel round bars manufacturer Vadodara

Submit Your Enquiry