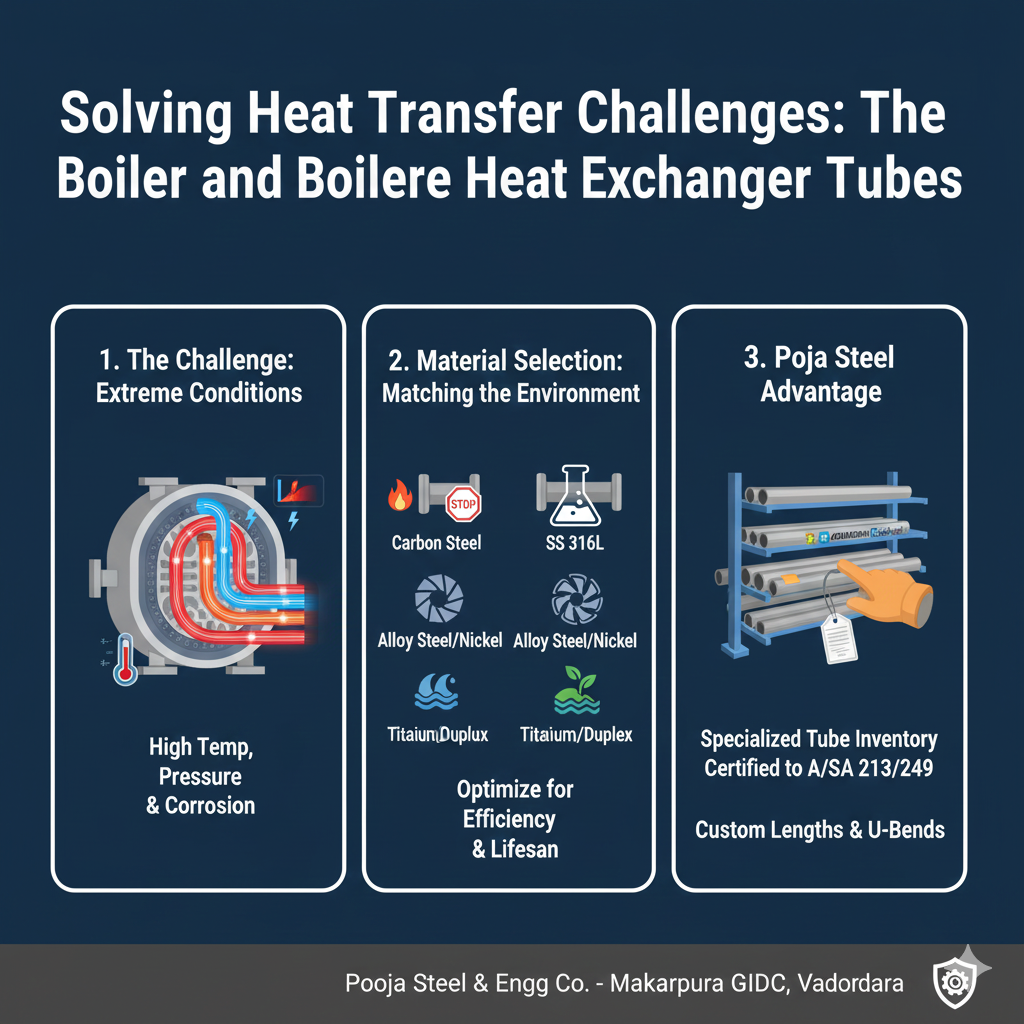

In power generation, petrochemicals, and HVAC industries, the efficient transfer of heat is paramount. This process relies entirely on the quality and integrity of the tubes used in boilers and heat exchangers. Choosing the right material ensures maximum thermal efficiency and minimum operational downtime. Key Demands on Heat Exchanger Tubes The tubes in a heat exchanger are subjected to two main stresses simultaneously: Thermal Stress: Extreme temperature differentials between the two fluids. Corrosion: Attack from corrosive fluids on both the inside and outside of the tube wall. Therefore, the ideal tube material must combine high thermal conductivity, exceptional high-temperature strength, and resistance to scaling and corrosion. Material Selection: Matching the Environment Standard Service: Carbon steel (e.g., ASTM A179) is often used for non-corrosive, low-temperature water/steam service. Corrosive Service: Stainless steel (especially SS 316L) is the standard for chemical processing and mildly acidic/alkaline fluids. High Temperature/Pressure: Alloy steel (e.g., P11, P22) or Nickel alloys (e.g., Inconel 600) are necessary for superheaters and aggressive furnace environments. Seawater/Chloride: Titanium or high-performance Duplex steel is often specified to prevent pitting and crevice corrosion. Pooja Steel Advantage: Specialized Tube Inventory Pooja Steel & Engg Co. maintains a specialized inventory of seamless and welded tubes in standard sizes, focusing on boiler and heat exchanger quality specifications (ASTM A/SA 213, A/SA 249). We can provide materials in U-bend or straight lengths, ensuring precise delivery for your fabrication schedule in Makarpura GIDC. Maximize your thermal efficiency. Source certified boiler and heat exchanger tubes from Pooja Steel & Engg Co.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.poojapipesandfittings.com/latest-update/solving-heat-transfer-challenges-the-role-of-boiler-and-heat-exchanger-tubes/81

Solving Heat Transfer Challenges: The Role of Boiler and Heat Exchanger Tubes

2025-12-31T06:30:01

In power generation, petrochemicals, and HVAC industries, the efficient transfer of heat is paramount. This process relies entirely on the quality and integrity of the tubes used in boilers and heat exchangers. Choosing the right material ensures maximum thermal efficiency and minimum operational downtime. Key Demands on Heat Exchanger Tubes The tubes in a heat exchanger are subjected to two main stresses simultaneously: Thermal Stress: Extreme temperature differentials between the two fluids. Corrosion: Attack from corrosive fluids on both the inside and outside of the tube wall. Therefore, the ideal tube material must combine high thermal conductivity, exceptional high-temperature strength, and resistance to scaling and corrosion. Material Selection: Matching the Environment Standard Service: Carbon steel (e.g., ASTM A179) is often used for non-corrosive, low-temperature water/steam service. Corrosive Service: Stainless steel (especially SS 316L) is the standard for chemical processing and mildly acidic/alkaline fluids. High Temperature/Pressure: Alloy steel (e.g., P11, P22) or Nickel alloys (e.g., Inconel 600) are necessary for superheaters and aggressive furnace environments. Seawater/Chloride: Titanium or high-performance Duplex steel is often specified to prevent pitting and crevice corrosion. Pooja Steel Advantage: Specialized Tube Inventory Pooja Steel & Engg Co. maintains a specialized inventory of seamless and welded tubes in standard sizes, focusing on boiler and heat exchanger quality specifications (ASTM A/SA 213, A/SA 249). We can provide materials in U-bend or straight lengths, ensuring precise delivery for your fabrication schedule in Makarpura GIDC. Maximize your thermal efficiency. Source certified boiler and heat exchanger tubes from Pooja Steel & Engg Co.

2025-12-31T06:30:01

Submit Your Enquiry